When you see a Calacatta Gold marble mosaic, what comes to mind. Is it just a beautiful design, or do you feel the history, the effort, the sheer human touch that went into it. These aren't just slabs of rock; they're stories etched in stone, a testament to patience and incredible skill. We're going to pull back the curtain and explore the fascinating journey these mosaics take, right from the earth to your walls and floors.

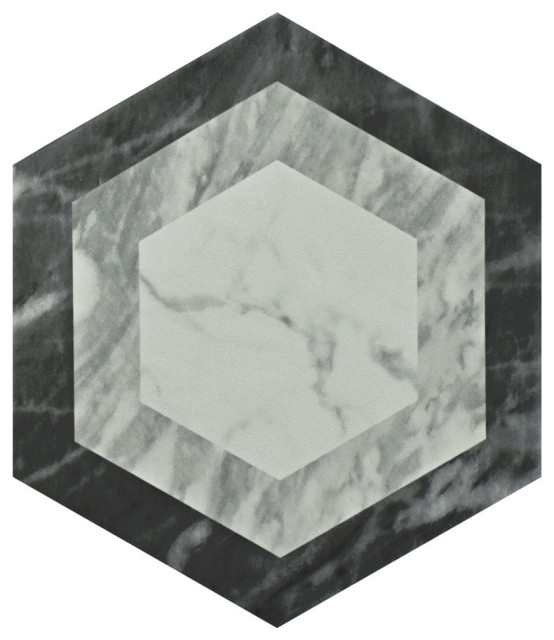

Calacatta Gold marble. Just the name conjures images of luxury and timeless elegance, doesn't it. This particular Italian marble is celebrated for its pristine white background, dramatic veining, and those signature flecks of warm gold. When this exquisite material is transformed into mosaics, it becomes something truly spectacular. But have you ever stopped to wonder how these intricate patterns are actually made. It's a process that blends nature's raw beauty with human ingenuity and a whole lot of painstaking work. Let's dive in and appreciate the true craftsmanship.

Quarrying: Nature's Initial Masterpiece

It all begins at the source, deep within the Carrara region of Italy, where Calacatta Gold is extracted. This isn't a simple digging operation. Skilled quarrymen use specialized tools and techniques to carefully free large blocks of marble from the mountainside. The goal is to minimize damage and preserve the integrity of the stone. Imagine the sheer scale of this: massive blocks being gently separated from their ancient berths. Each block is a unique canvas, its veins and patterns dictated by geological forces over millennia. It's here that nature lays down the foundation for the artistry to come.

Selection and Sourcing: Choosing the Finest

Not all Calacatta Gold is created equal, and selecting the right pieces for mosaics is a crucial step. Artisans and stone specialists meticulously examine the quarried blocks. They're looking for specific characteristics: the purity of the white, the boldness and flow of the gray veining, and, of course, the presence and distribution of those coveted gold hues. The best sections are often chosen for mosaics because the smaller pieces allow for a more controlled and detailed display of the marble's unique beauty. It’s like a painter selecting the perfect pigments for their palette.

Cutting and Shaping: Precision in Every Piece

This is where the real transformation begins. The selected marble slabs are brought to workshops. Here, skilled craftspeople use advanced machinery, like waterjet cutters and specialized saws, to slice the marble into smaller pieces, known as tesserae. For mosaics, these pieces are often surprisingly small, sometimes just a few centimeters across. The cuts must be incredibly precise to ensure that the pieces fit together perfectly later on. Some designs even call for hand-cutting or chiseling to achieve unique shapes and textures, adding another layer of artisanal touch. It requires immense focus and a steady hand, often for hours on end.

Designing and Layout: The Blueprint of Beauty

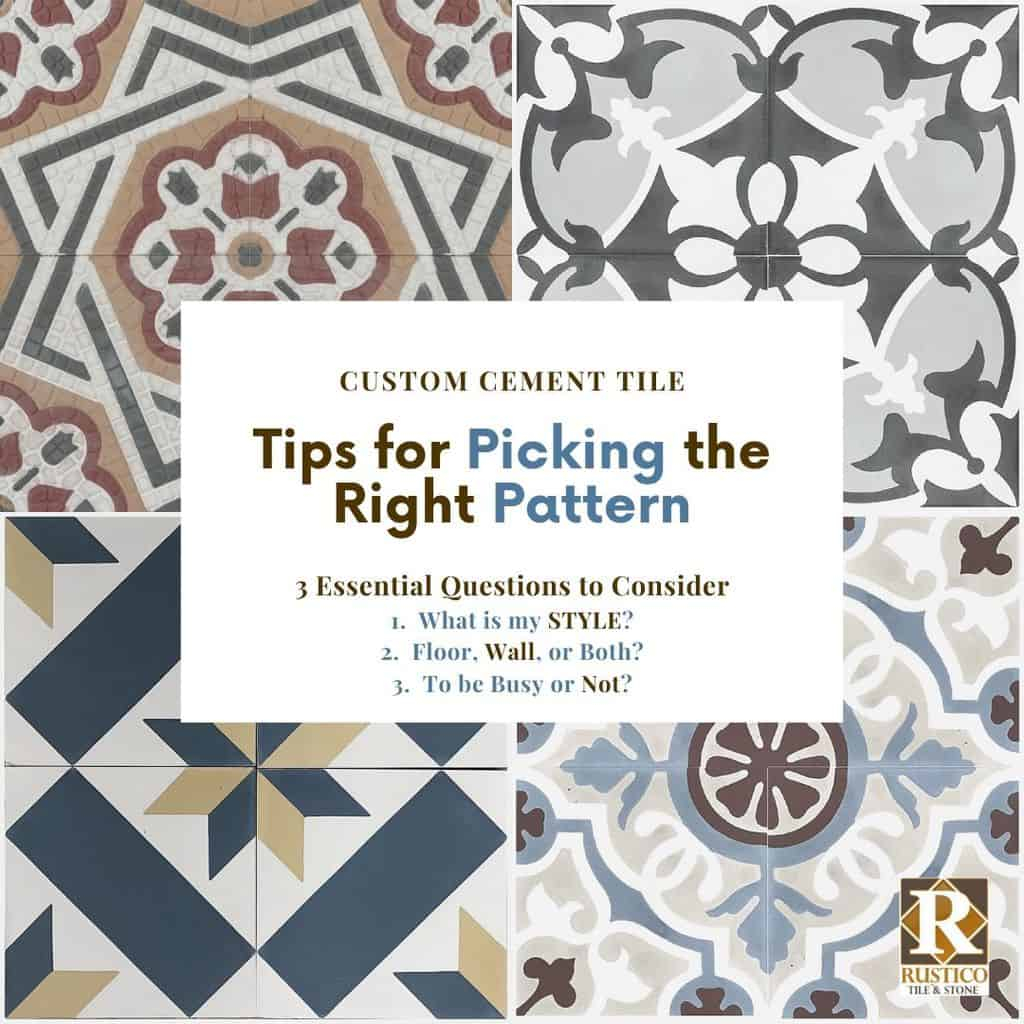

Before any assembly, there's the design phase. This can range from classic geometric patterns to intricate pictorial scenes. Designers and mosaic artists work closely together. They might create detailed drawings or digital renderings. Then, the actual layout process begins. The tesserae are arranged on a backing material, often mesh or paper, following the design. This is a critical stage where the visual flow and balance of the mosaic are established. The placement of each individual chip of marble is deliberate, ensuring the veining and colors create a harmonious and captivating image. It’s a puzzle, but one where each piece is a work of art in itself.

Assembly: Piecing Together the Vision

This is arguably the most labor-intensive part. Each small piece of Calacatta Gold marble is carefully placed according to the design. They are often adhered to the backing material using specialized adhesives. For the highest quality mosaics, especially those intended for floors or high-traffic areas, the tesserae might be set into a bed of mortar. This traditional method, known as 'tesserae by tesserae,' ensures incredible durability and a seamless feel. Imagine a mosaicist hunched over their work, meticulously placing hundreds, even thousands, of tiny stone fragments. It’s a process that demands patience and an incredible eye for detail.

Finishing and Grouting: The Polish and Perfection

Once all the pieces are in place and the adhesive or mortar has cured, the mosaic undergoes finishing. This can involve a light sanding or polishing to ensure all the surfaces are smooth and even. Then comes the grouting. Grout fills the small spaces between the tesserae, unifying the design and adding structural integrity. The color of the grout is a crucial choice, as it can either blend in with the marble or create a subtle contrast, further defining the pattern. Finally, a sealant is often applied to protect the marble from stains and moisture, ensuring the mosaic's longevity and enduring beauty. It’s the final flourish that brings the entire composition to life.

So, the next time you encounter a Calacatta Gold marble mosaic, take a moment to truly appreciate it. It's more than just a decorative element; it's a tangible piece of artistry, a testament to the skill of quarrymen, stone cutters, designers, and mosaicists. From the rugged mountains of Italy to the meticulously assembled pattern, each step in the creation process is infused with dedication and a deep respect for the material. These mosaics are not just beautiful; they are enduring legacies, crafted by hand and heart, designed to bring timeless elegance into our lives for generations to come. It’s a beautiful fusion of nature’s grandeur and human dedication.