Ever walk into a room and just feel… right? Often, the flooring plays a huge part in that feeling. And when it comes to floors that whisper elegance and stand the test of time, white encaustic porcelain tiles are a real showstopper. But have you ever stopped to think about how these intricate, beautiful tiles actually come to be? It's not just about pressing a pattern, you know. There's a whole lot of skill and artistry involved in creating these masterpieces for your home.

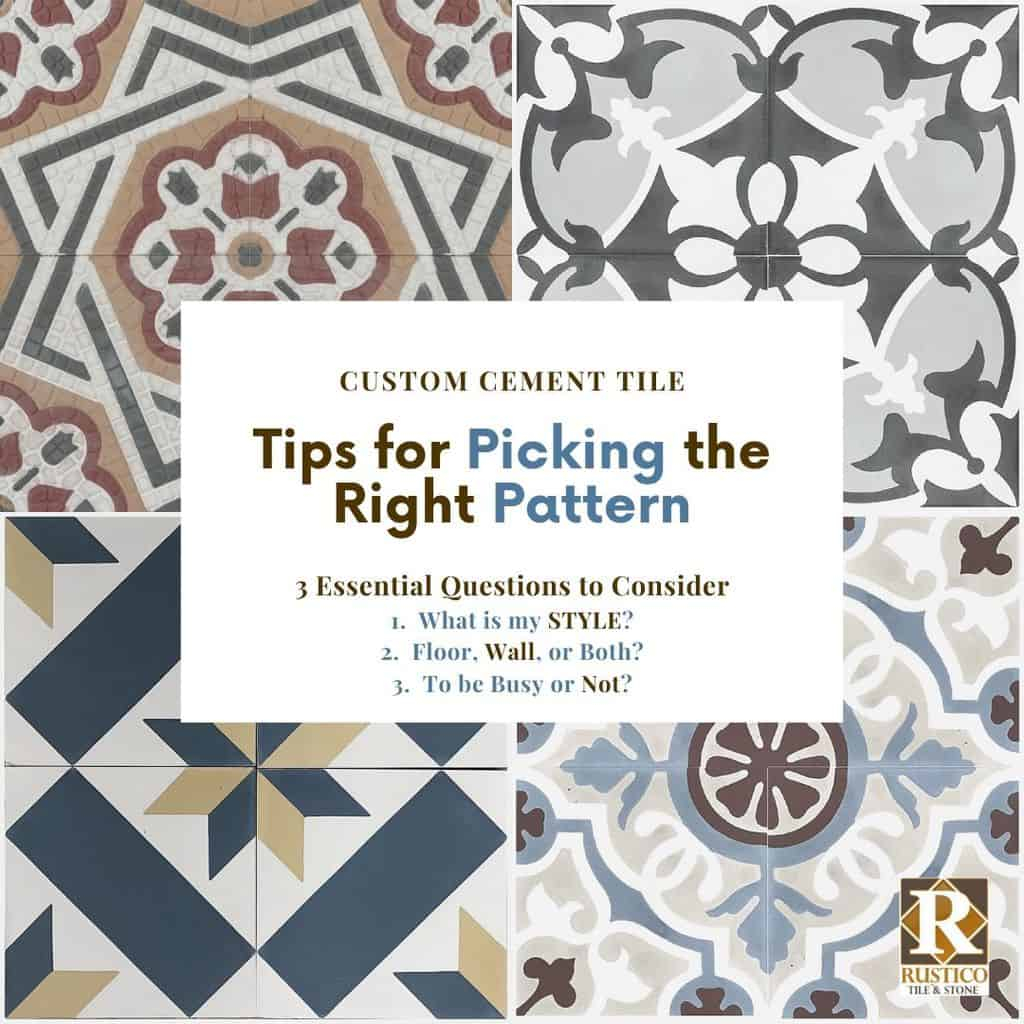

White encaustic porcelain floors are having a major moment, and honestly, it’s no surprise. They bring a touch of vintage romance, a splash of modern sophistication, and a whole lot of character to any space. Unlike simple printed tiles, true encaustic tiles have their patterns built right into the tile itself, using different colored clays. This technique, which dates back centuries, creates a depth and richness that you just can't replicate. So, what’s the secret sauce? It’s all in the meticulous process and the skilled hands that bring these designs to life.

The Art of Clay: The Foundation of Encaustic

The magic of encaustic porcelain truly begins with the clay. Unlike standard porcelain tiles, encaustic tiles use a blend of different colored clays, carefully mixed and prepared. Think of it like a painter choosing their pigments. The quality and type of clay are crucial for the final look and durability. Skilled artisans understand how these clays will behave during the pressing and firing stages – how they’ll hold their color, resist wear, and bond together. It’s a delicate balance, and getting it right is the first step in creating that signature encaustic look.

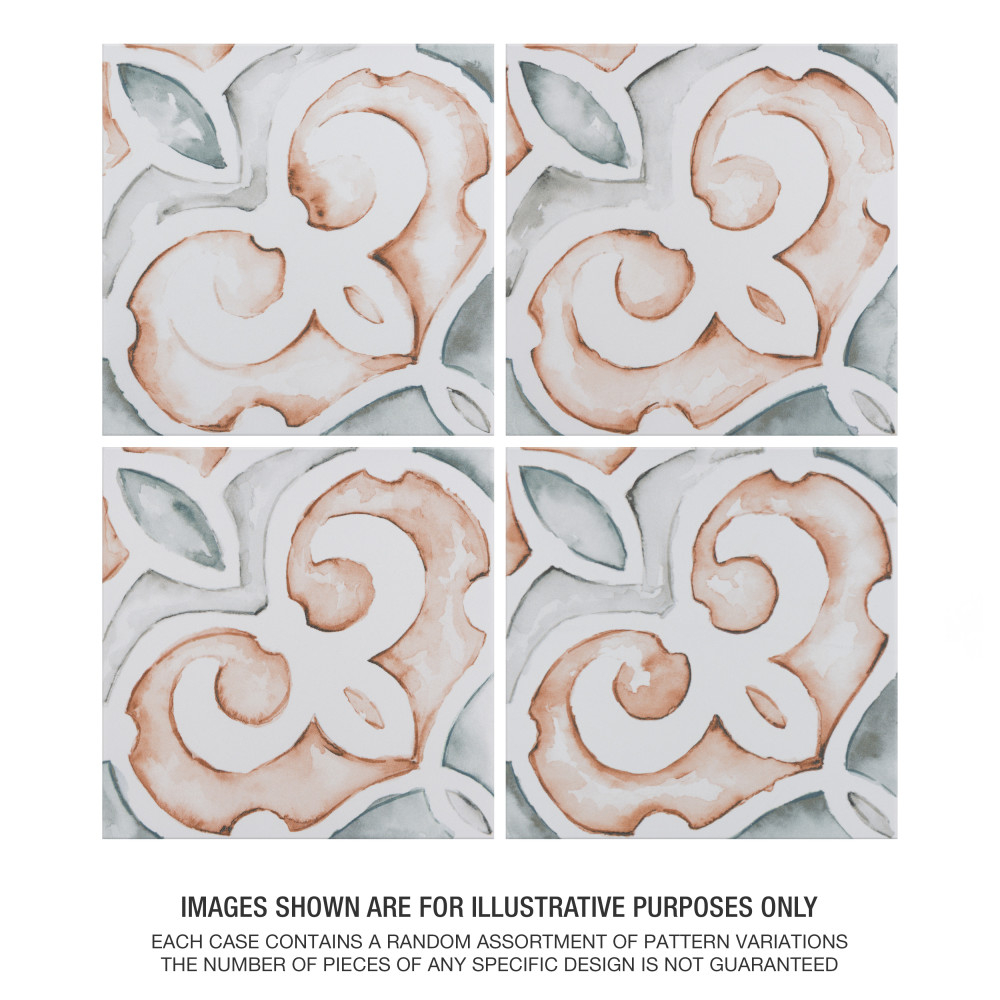

Pattern Play: Designing and Crafting the Molds

The intricate patterns we love on white encaustic porcelain tiles aren't just painted on. They’re created by pressing colored clay into a mold. This is where the real design skill comes into play. Artisans, or sometimes specialized designers, meticulously create the patterns. Then, these designs are translated into durable molds, often made from plaster or metal. The precision required here is immense. Even a slight imperfection in the mold can lead to a flawed tile. It’s about ensuring clean lines and crisp details, so each tile is a perfect little piece of art.

The Pressing Process: Where Clay Meets Design

This is the heart of the encaustic process. Once the molds are ready, colored clay is carefully placed into them. Then, under immense pressure, the different colored clays are fused together. It's like a high-tech, high-art sandwich. The pressure ensures that the colors penetrate deeply into the tile, creating a pattern that won't wear away. This isn't a quick process; it requires controlled pressure and precise timing. Imagine the focus needed to ensure each tile receives the exact amount of force to create a perfect, unified design. It’s a blend of engineering and artistry, really.

Firing Up: Baking in Durability and Beauty

After pressing, the tiles are carefully dried and then fired in a kiln at very high temperatures. This firing process is what transforms the raw clay into hard, durable porcelain. But for encaustic tiles, it’s also about locking in those vibrant colors and intricate patterns. The firing needs to be just right – not too hot, not too cool, and for the correct duration. Too much heat can cause the colors to bleed or the tile to warp. Too little, and it won't be durable. It’s a crucial stage that requires a deep understanding of material science and a keen eye for detail.

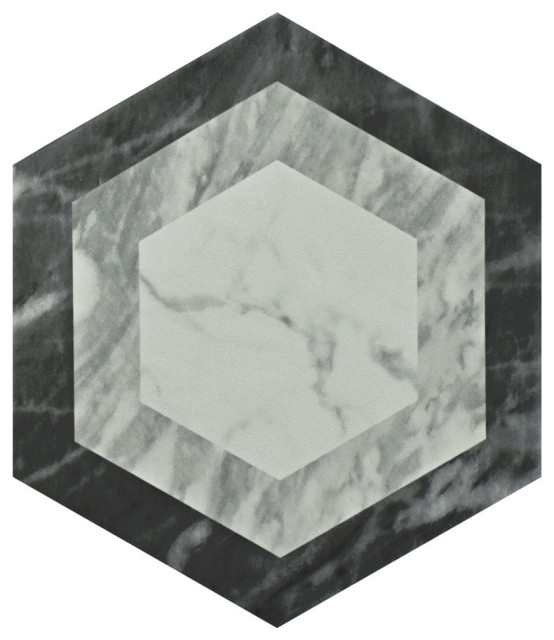

The White Encaustic Distinction: Why White Stands Out

While encaustic tiles come in a rainbow of colors, the white variations hold a special place. Achieving a crisp, clean white that also allows intricate patterns to shine requires a specific expertise. The white clay itself needs to be of exceptional quality to avoid any undesirable undertones. Furthermore, the contrast between the white and the accent colors is what truly defines the pattern. This means the precision in the pressing and firing stages is even more critical to ensure those lines remain sharp and distinct, giving the floor that timeless, elegant appearance. It’s a subtle art, but one that makes a huge difference.

Maintaining the Masterpiece: Care and Longevity

One of the best things about white encaustic porcelain floors is their longevity, provided they’re cared for properly. Because the color is embedded within the tile, they’re incredibly resistant to fading and wear. Regular sweeping and occasional damp mopping are usually all that’s needed. It’s best to avoid harsh chemical cleaners, as they can dull the finish over time. Think of it as preserving a piece of art; gentle care ensures its beauty lasts for generations. It’s a floor that truly grows with your home.

So, the next time you admire a beautiful white encaustic porcelain floor, you’ll know it’s more than just a surface covering. It’s a testament to centuries of tradition, a product of skilled craftsmanship, and a commitment to enduring beauty. From the careful selection of clays to the precise pressing and firing, each step in the creation of these tiles is a deliberate act of artistry. It’s this dedication to quality and detail that makes white encaustic porcelain floors a truly timeless and valuable addition to any home. They’re not just floors; they’re foundations for memories, built to last.