Think about the last time you sat in something that felt both comfortable and sturdy. Maybe it was a chair with a metal frame and fabric cushions, or perhaps a jacket that combined leather with synthetic materials. These combinations aren't just random choices—they're thoughtful fusions designed to bring together the best of both worlds. Fabric and metal fusion represents one of the most exciting frontiers in material science and design, creating objects that are not only visually striking but also built to last.

The marriage between fabric and metal might seem unlikely at first glance. After all, fabrics are soft and flexible while metals are hard and rigid. But when designers and engineers get creative, they discover that combining these materials can result in something truly special. This fusion isn't just about aesthetics—it's about creating products that can handle daily wear and tear while still looking good. From furniture to fashion, from automotive interiors to architectural elements, this combination has become increasingly popular because it offers practical benefits alongside visual appeal. The secret lies in understanding how each material contributes to the overall performance and appearance of the final product.

Understanding Material Properties

Before diving into how fabric and metal work together, it's essential to understand what makes each material unique. Fabrics are typically made from natural fibers like cotton, wool, or silk, or synthetic alternatives such as polyester and nylon. They offer comfort, flexibility, and breathability. Metals, on the other hand, provide strength, durability, and structural support. They can withstand high temperatures, resist corrosion, and maintain their shape under pressure. When these two types of materials come together, they create a synergy that neither could achieve alone.

For instance, a metal frame provides the backbone for a chair, ensuring it won't collapse under weight. Meanwhile, fabric upholstery adds comfort and style. The metal keeps things stable while the fabric makes them pleasant to sit on. It's a classic example of how different properties complement each other to create something better than either material could do independently.

Durability Through Strategic Combination

One of the biggest advantages of fabric-metal fusion is enhanced durability. Consider outdoor furniture that needs to withstand weather conditions. A metal frame can resist rust and corrosion, while a fabric cover can be treated to repel water and UV rays. Together, they form a system that lasts much longer than either component would alone.

Key factors contributing to this durability include:

• Corrosion resistance from metal components• Weather protection from treated fabric layers• Structural integrity provided by metal frameworks• Wear resistance through proper material selection

This approach isn't limited to furniture. In automotive design, metal frames provide safety structure while fabric interiors offer comfort and noise reduction. The strategic placement of materials ensures that each element performs its role effectively without compromising the other.

Aesthetic Appeal and Design Flexibility

Beyond practical benefits, fabric and metal fusion opens up incredible design possibilities. The contrast between soft, flowing fabric and hard, angular metal creates visual interest that's hard to achieve with single materials. Designers can play with textures, colors, and shapes to create unique looks.

Some aesthetic considerations include:

• Color coordination between fabric and metal finishes• Texture contrast from smooth metal against rougher fabric surfaces• Shape balance between geometric metal forms and organic fabric curves• Pattern integration that flows across both materials

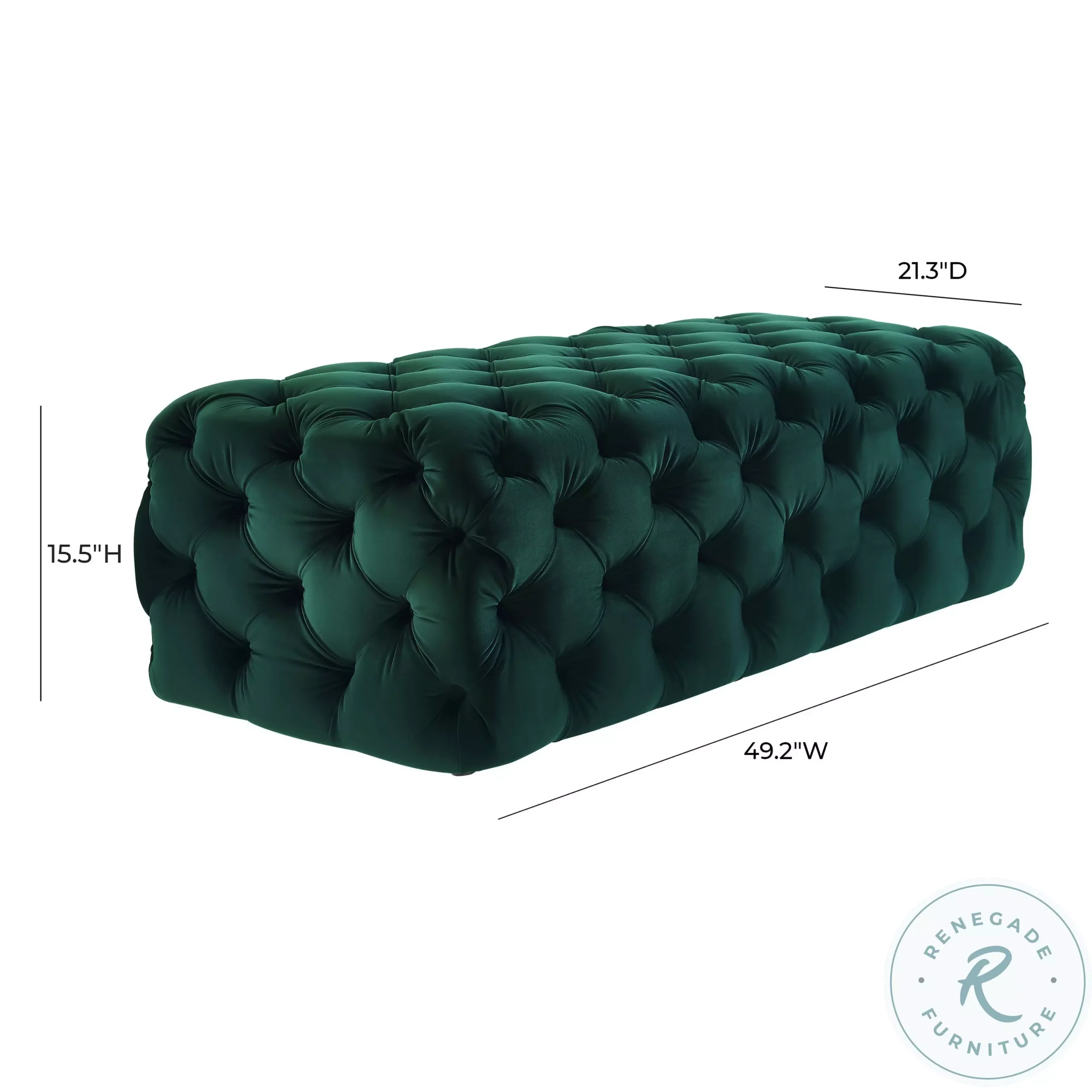

Take luxury sofas, for example. A sleek chrome or brushed steel frame paired with rich velvet or premium leather creates an elegant look that feels both modern and timeless. The metal adds sophistication while the fabric brings warmth and comfort.

Technological Advances in Joining Methods

The success of fabric-metal fusion depends heavily on how well these materials bond together. Over the years, technology has evolved significantly to improve this process. Modern techniques allow for stronger connections between dissimilar materials.

Popular joining methods include:

• Welding for permanent metal connections• Adhesive bonding for secure fabric attachment• Mechanical fastening using specialized hardware• Thermal bonding for heat-sensitive applications

Innovations in adhesives have been particularly important. Today's industrial glues can create bonds that are stronger than the materials themselves, ensuring that the fabric stays securely attached even under stress. These advances mean that fabric-metal products can be built to last decades rather than just years.

Applications Across Industries

Fabric-metal fusion finds applications in numerous sectors, each with specific requirements and challenges. The automotive industry uses this combination extensively for seats, door panels, and interior trims. The metal components provide structure and safety features while fabric covers enhance passenger comfort and reduce noise.

Other major areas include:

• Furniture manufacturing where metal frames support fabric upholstery• Architecture where metal structures hold fabric installations for decorative or functional purposes• Fashion where metallic accents add glamour to textile garments• Industrial equipment where metal parts work alongside fabric components for protection or comfort

Each application requires careful consideration of environmental factors, usage patterns, and maintenance requirements. For example, a fabric-metal combination used in a hospital setting must meet strict hygiene standards, while outdoor applications need weather-resistant treatments.

Maintenance and Longevity Tips

To get the most out of fabric-metal fusion products, proper care is crucial. Regular cleaning and inspection can extend their lifespan significantly. Here are some practical tips:

• Clean fabric surfaces according to manufacturer instructions• Protect metal components from moisture and corrosion• Check for loose connections or worn areas periodically• Address small issues before they become bigger problems• Follow recommended maintenance schedules

Many modern fabric-metal combinations come with warranties, but following care instructions is still essential. Some fabrics may require professional cleaning, while others can be spot-cleaned at home. Metal parts often benefit from periodic lubrication and polishing to maintain their appearance and function.

Fabric and metal fusion represents more than just a trend—it's a thoughtful approach to creating products that combine the best qualities of both materials. Whether it's a comfortable chair that will last for years or a stylish jacket that withstands daily wear, this combination delivers on both function and form. As technology continues to advance, we'll likely see even more innovative ways to merge these materials, creating new possibilities for designers and consumers alike. The key is understanding how to leverage each material's strengths while addressing potential weaknesses through smart design and proper construction. When done right, fabric-metal fusion creates lasting value that goes beyond simple aesthetics.